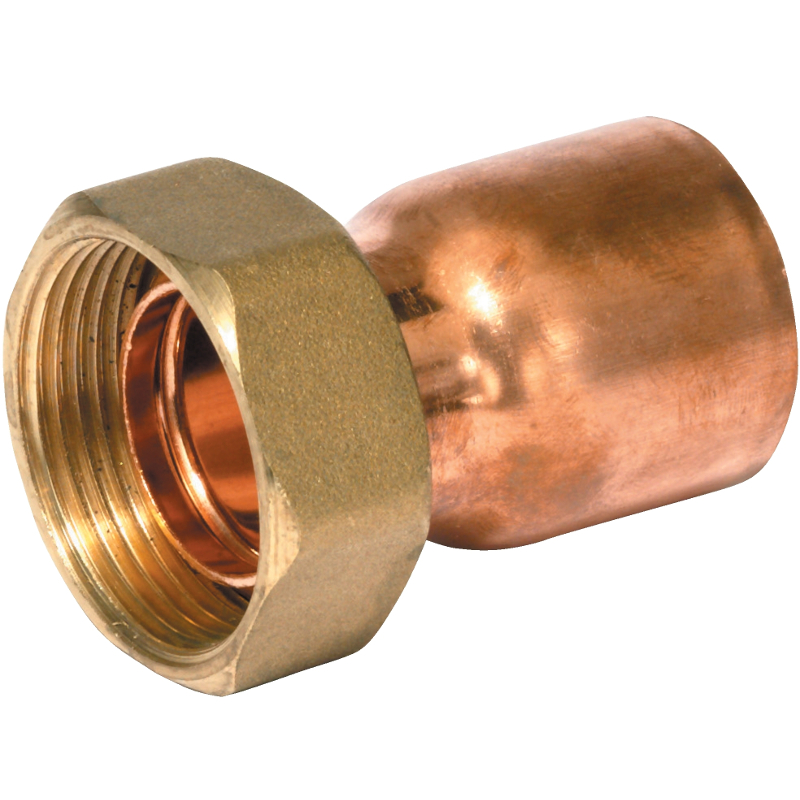

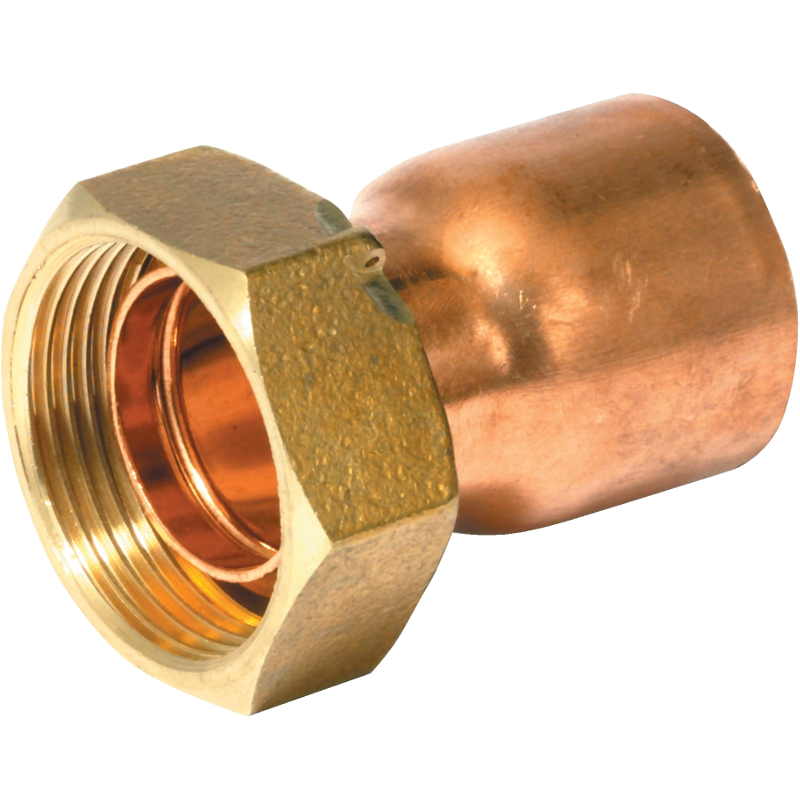

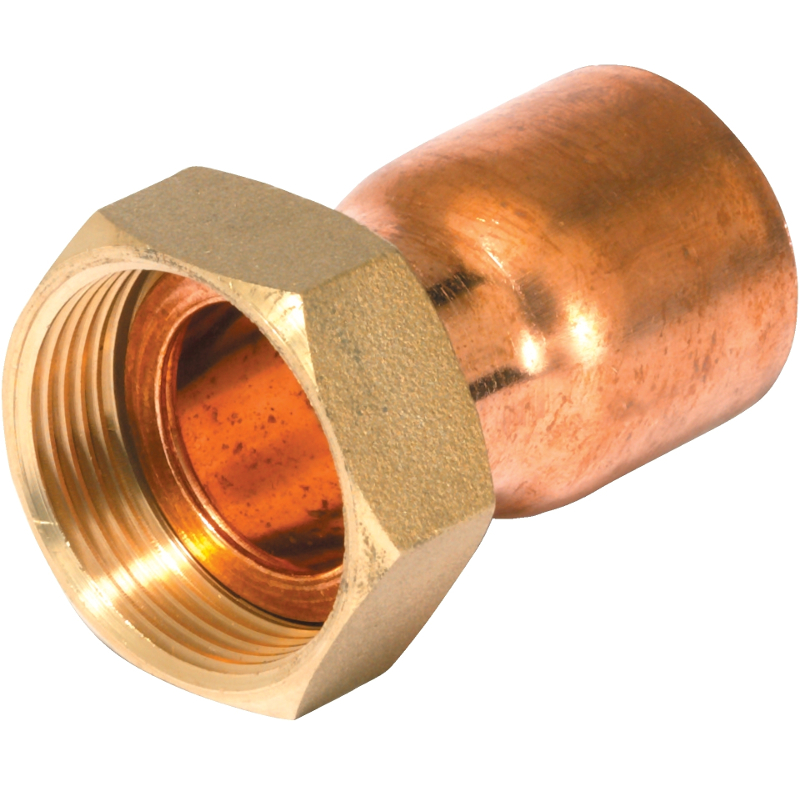

End Feed Fittings for Copper Tube

rmmcia offers the family of end feed fittings for copper tube to satisfy your needs in installations of copper tube with capillary soldering. An assortment of threading - soldering accessories for copper pipe connection, including elbows, tees, straight and curved unions, couplings, etc.

The end of the fitting for soldering is for metric tubing (in millimetres) under european standard. In soldering - thread accessories the thread is according to ISO 228. Mention again the convenience to use a sealant on the thread connection, such as hemp fibre or another such as Teflon or similar.

The products of the family presents the references ordered by their size denominated in inches or fractions of an inch for the threaded end, and in millimetres for the soldering ends in reference to the diameter of the copper tube. They can be used in applications such as the supply of water, in the distribution of sanitary water, in radiator heating installations and for the conveyance of other fluids compatible with copper tube.

It is interesting to note that copper is a material with many advantages such as an excellent corrosion resistance, good mechanical strength, in addition to its ease of operation: deformation, cutting and welding. Highly recyclable, non-toxic and its inhibitory capacity in the development of microorganisms make it ideal for transporting drinking water.

Talking about the manufacturing material used on these brass fittings mention brass CW617N UNE-EN 12165 for forged parts, brass UNE-EN 1982 CB753S for casted parts, brass CW614N UNE-EN 12164 for bar machined items, and copper for tube segments forming (example the straight or bent tap connectors, with a nut made in brass and a copper tube segment).

In terms of manufacturing standards, for this family of end feed fittings for copper tube the UNE-EN 1254-1 and EN 1254-4 are considered for related aspects on soldering accessories, UNE-EN 1057 for copper tube characteristics and UNE-EN ISO 228 for threading. The manufacture and marketing of these products is made through our ISO 9001 certified plant, ensuring the quality of the production and the processes of marketing and customer service.

Herewith we illustrate how to install them, how to do the transition from soldered to threaded fittings (with English subtitles).