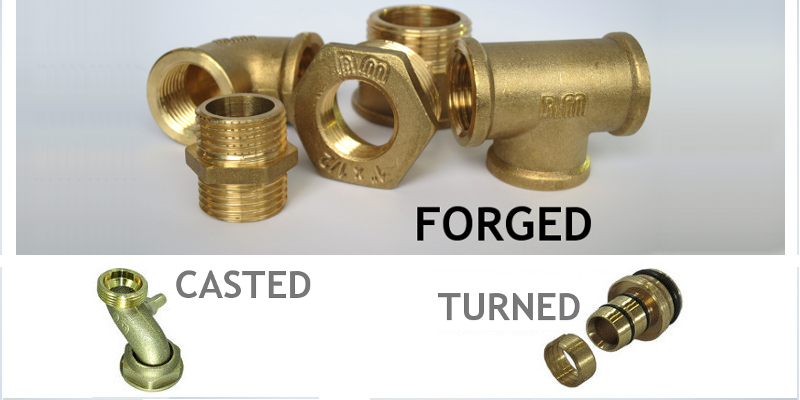

Brass fittings by rmmcia are made in brass, but three different types of brass are used depending on the manufacturing process. The reason why different brass are used for different fittings is simple, proportion of their components bring certain properties to brass making it optimal for a type of manufacturing or other type. Though seems difference is minimal, as basic brass components are in an approximate proportion of 60/40 for copper/zinc, in minor measure there are other metals and chemical elements such as aluminium, iron or nickel.

Subtle components difference among types of brass alloys facilitates a given manufacturing technique, considering fusion temperature and malleability and ductility, for instance.

Generally speaking, pieces requiring shape freedom don’t start from brass bar, but they are casted in metallic moulds where liquid brass is poured, at fusion temperature. This brass is following regulations UNE-EN 1982 CB753S and CB755S, and it is composed by approximately 59% of copper and 37% or 39% of zinc respectively.

Forged parts are the pieces manufactured in big production batches; they are the most consumed among our portfolio of products. These commonly are elbows, tees, nipples, brass unions… of medium or small size. Their brass arrive as a bar which is subject to low temperature (680ºC-790ºC) so pieces are manufactured by stamping, though finally also suffers a turning process for adding, for example, a thread. Their brass fulfills regulation UNE-EN 12165 CW617N, with a higher zinc level, of 40%. This is the method we work the most at rmmcia and a higher number of references generate, that’s why we dedicated a special chapter in our blog. CLICK to see

Finally there are the turned fittings, which we identify by its cylindrical shape, as they become from brass bar and their manufacturing is done in lathe and by machining (for example the inserts within PEX and multilayer fittings). It is a high precision machining conferring a high symmetry to the pieces. They are manufactured in brass UNE-EN 12164 CW614N, of high ductility and easy to work with at a colder temperature. The machining is done thanks to tools while the piece is turning at an automatic or semiautomatic lathe. Nowadays there’s a more advance technique, the CNC or Computer Numeric Control, allowing programming so a robot can work with almost total autonomy.

It cannot be identified at first sight the type of technique used, therefore what sort of brass has been used for producing a given piece, so in order to know with certainty the type of brass and manufacturing process of a reference, we strongly recommend to asking us.